Selecting the best females based on genomic testing has resulted in rapid gains at Grosvenor Farms, Cheshire, where top notch management is helping heifers fulfil their genetic potential.

The ability to drive rapid genetic gain in specific traits is the main reason Grosvenor Farms’ dairy and resource manager David Craven would not be without genomic testing.

Mr Craven started genomically screening every heifer calf born at Grosvenor Farms two years ago in the knowledge the farm would hit expansion targets of 2,500 cows by 2019.

Having previously focused on upping cow numbers, rather than heavy selection, genomic screening would allow selection pressure to be increased, resulting in big gains in desirable traits.

A ‘test’ on 100 cows and their offspring in 2015 gave him the confidence to roll the strategy out across the herd.

He says: “That’s where we saw the accuracy of genomic testing.

What we predicted those heifers to do, they did.” Having pushed for milk yield for many years, Mr Craven is now breeding for kilos of fat while maintaining fertility and good stature.

Udder conformation and teat placement are also crucial for fast milking on the threetimes-a-day milking system.

Cows average 12,500 litres at 4% fat and 3.5% protein.

The youngstock shed is open sided with an automatic curtain on the south westerly side, which will open or shut depending on wind speed and temperature

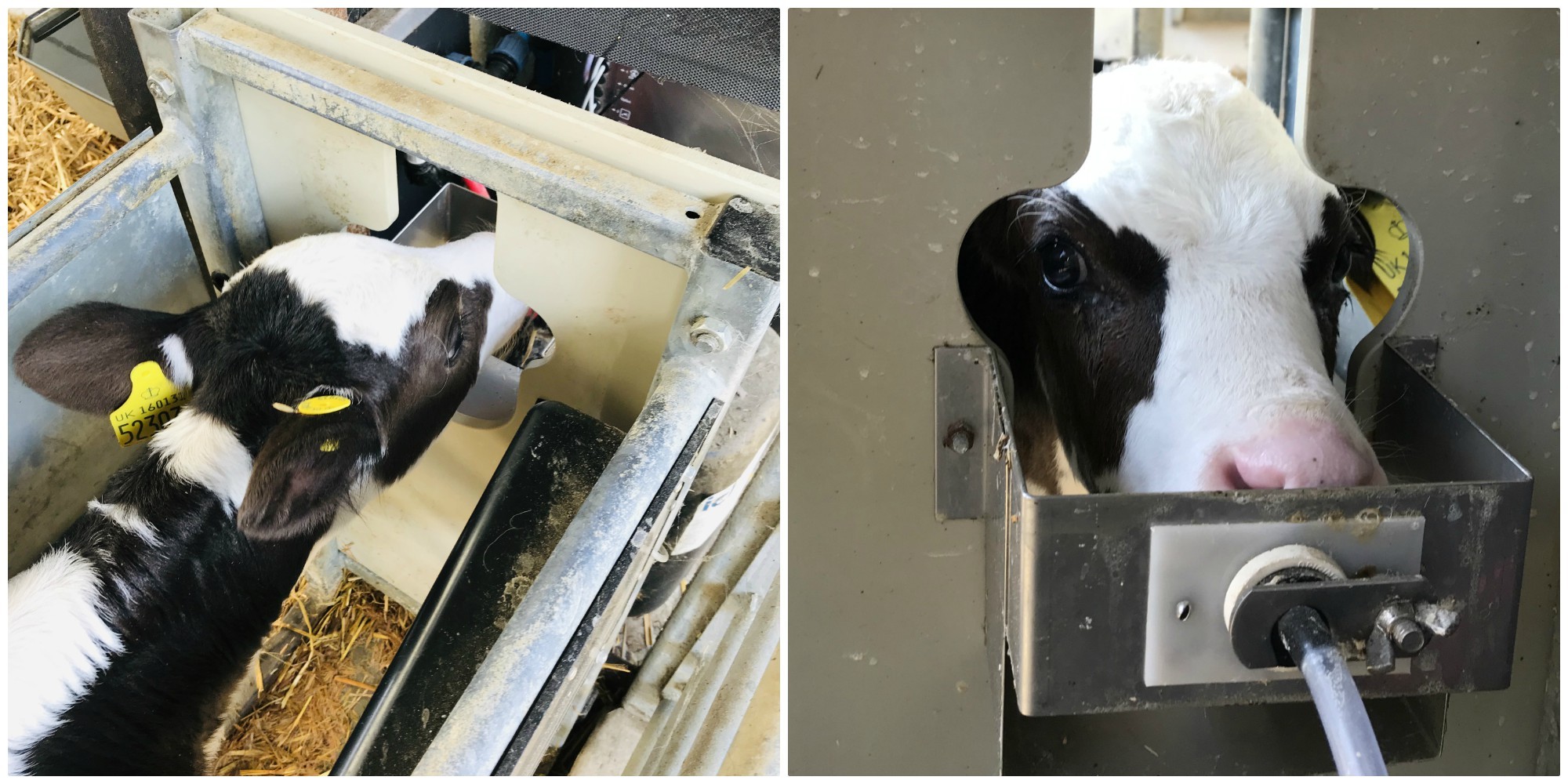

All heifer calves are tagged with a combined genomic test and management tag at birth as part of Cogent’s Precision DNA service.

When the genomic proof is received, females will then be ranked for kg of milk fat, along with fertility, feet, stature and somatic cell counts.

Mr Craven says this is a more useful selection criteria than £PLI.

“Our herd is quite tight so £PLI is £380-£390 to £650-£700.

The core is in the middle of that.

There are more outliers on kg of fat not £PLI,” he says.

The process has proved particularly useful in identifying outliers which may have been ‘average’ on parent average, but have proved to be ‘super heifers’ or ‘poor’ when genomically tested.

Mr Craven says: “At least 60% don’t move off their parent average, but what you do find is those that could be average on parent average turn out to be poor animals.

You wouldn’t pick that up without genomics.”

All heifer calves are tagged with a combined genomic test and management tag at birth

Genetic gains achieved from genomic testing at Grosvenor Farms

- Top 10 pre-calved heifers for £PLI

- 2017-2018: Averaged £600 £PLI and 23kg of milk fat

- 2018-19: Averaged £670 £PLI and 29kg of milk fat Heifers aged one-two year’s old (all animals tested in the last 12 months):

- Top milk: 1,010kg

- Bottom milk: 50kg Heifers under one-year-old (for example, new calves produced from genomically selected females – all animals tested in the last 12 months):

- Top £PLI: £673 jBottom £PLI: £140

- Top milk: 1,179kg jBottom milk: 62kg

sexed semen

The bottom 25-30% of females will be sold at weaning, while the rest will be bred to Sexed ULTRA 4M semen.

About 20% of the best first lactation and 20% of the best second lactation females are also put to sexed semen.

Everything else is going to Aberdeen-Angus sires from Cogent.

A breeding programme is drawn together by Cogent, with about six bulls used across the heifers.

To get the most from genomic testing, Mr Craven believes it is worth deselecting a relatively high number of females – just selecting out one or two females will not realise its full potential.

The benefits of genomically testing have been realised relatively fast at Grosvenor Farms (see ‘Genetic gains achieved from genomic testing at Grosvenor Farms’ panel), Mr Craven says: “By selectively breeding we saw a very big improvement in the first year, especially with fat.

That has slowed down now, as we don’t have as many outliers, but there are still improvements to make.” Moving forward, this will include selecting animals using EcoFeed – a new breeding index which evaluates feed intakes and how well an animal converts that into milk.

“In the next two-five years that’s going to be a big selection pressure,” says Mr Craven.

Environment maximises genetic potential

Following herd expansion, Grosvenor Farms invested in a dedicated youngstock unit which has been designed to deliver the best possible environment underpinned by top notch management.

David Craven says: “It doesn’t matter how good your genetic selection is, if you don’t manage them correctly.”

COLOSTRUM

“Colostrum management is absolutely key,” says Mr Craven.

“It’s about making sure that once it’s taken from the cow it’s kept appropriately and not allowed to stand as bacteria can grow so quickly.

And delivering that colostrum to the calf quickly,” he adds. The dedicated team follow strict colostrum protocols:

- All colostrum is pasteurised to help with Johne’s control

- Colostrum is tested using a refractometer and will only be fed if it tests >23%

- Calves receive 10% of their bodyweight in colostrum within one-and-a-half hours of birth (for example, four litres for a 40kg calf)

- A second colostrum feed is delivered eight hours later

- This will be whatever the calf will drink, but is usually two-three litres once calves have received colostrum, they are moved to the dedicated youngstock shed

BUILDING DESIGN AND ENVIRONMENT

The youngstock shed is open sided with an automatic curtain on the south westerly side, which will open or shut depending on wind speed and temperature. Calves are managed in groups of 20.

Each group has access to an outside loafing area, which can be shut off with sheeted gates in inclement weather.

The farm is currently working with Willows Farm Vets to reduce respiratory challenges in the calves.

The plan is to install a positive pressure ventilation tube to aid air movement.

AUTOMATED MILK FEEDING

Calves are initially kept in pairs and fed three litres of Heiferlac calf milk replacer twice-a-day until they are strong and used to teat feeding.

They then move onto a Volac FörsterTechnik automated milk feeding system.

The barn has eight feeders, with two groups of 20 calves sharing each machine.

Mr Craven says: “You have a feeding programme and you know the milk is mixed consistently.

There’s quite a lot of information that can help with the management of the calves. And it helps labour.”

HYGIENE

The milking machine is maintained and cleaned regularly.

When a pen is emptied it will be mucked out, steam cleaned, disinfected with a product which is effective against cryptosporidiosis. The pen will then be rested for two weeks if possible.